Potential Hydrologic Impacts of Lithium Extraction

Project Description

As the United States and other countries shift from fossil fuels to renewable energy, more lithium will need to be produced to meet the increased demand for energy storage. With 85% of the known lithium deposits in the United States, Nevada has the potential to be a key lithium producer. Lithium-containing brines, hard rock, and clay are the target geological settings for producing economical amounts of lithium. The mined lithium will be used primarily for energy storage in rechargeable batteries, which are widely used in electric vehicles and portable electronic devices.

The findings in the report from this project can be used as an outline for a detailed and comprehensive examination and assessment of the potential impacts of lithium extraction on water resources in Nevada, including both surface water and groundwater. A Hydrologic Risk Assessment Checklist, or “Checklist,” has been developed as a standardized approach to quantify the level of hydrologic risk of a proposed lithium mine and to compare the relative risk between lithium projects. Additionally, a Hydrologic Impacts Framework, or “Framework,” has been developed for a more detailed evaluation of planned or future lithium mines in Nevada. Overall, hydrologic impacts from lithium extraction are a function of the lithium resource type (i.e., brine, clay, or rock), hydrologic and geologic conditions, and facility operations (i.e., scale of production, extraction technique, and processing technique). The Checklist and Framework lead the user through several critical questions pertaining to a lithium project’s location, environmental conditions, design, and operational plan to identify the potential impacts on water resources. The results of applying the Checklist and Framework to a future lithium mine will identify areas of uncertainty with respect to potential hydrologic impacts.

Disclaimer: Neither the Checklist nor Framework should be used as a comprehensive review that covers all environmental risks, or as an alternative to intensive, site-specific hydrologic impact assessments that precede regulatory approval. Instead, the Checklist and Framework may be used to identify areas of uncertainty related to the potential for hydrologic impacts associated with lithium extraction. After applying these tools, more detailed site-specific analyses should be considered and implemented to address the areas of uncertainty. The Checklist and Framework may be paired with other assessments to identify areas or waters of concern (e.g., pairing with an ecological assessment to identify aquatic habitat that may be at risk).

CONTACT

Daniel Saftner

daniel.saftner@dri.edu

Kevin Heintz

kevin.heintz@dri.edu

Ron Hershey

ron.hershey@dri.edu

LOCATION

Desert Research Institute

2215 Raggio Parkway

Reno, NV 89512

DIVISION

Hydrologic Sciences

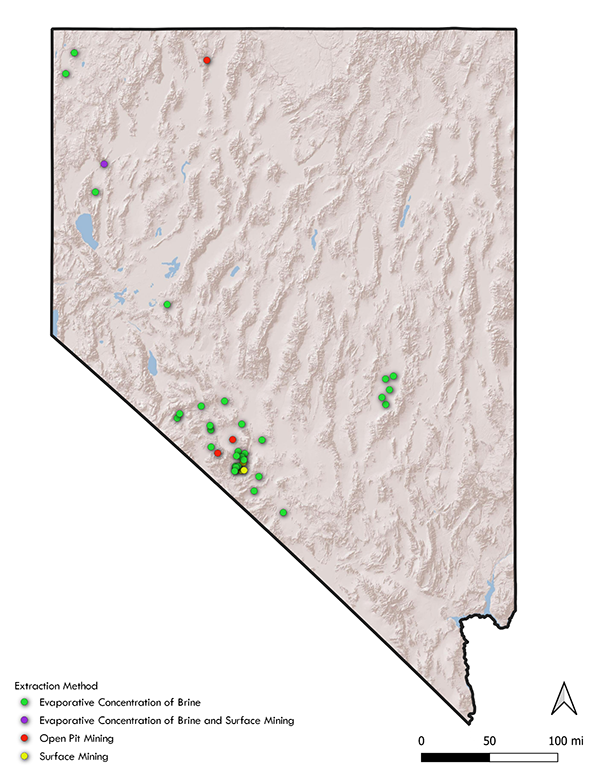

Figure 1. Map of proposed lithium extraction sites (colored by extraction method) in Nevada as of August 2022. Modified from Parker et al. (2022).

Hydrologic Risk Assessment Checklist

The Checklist is a series of questions that require Yes/No responses, with a “Yes” response indicating greater hydrologic risk than a “No” response. Generally, the potential for hydrologic risk increases with the total number of “Yes” responses for the project under evaluation. The Checklist provides a space for notes to allow the user to capture nuances, complications, or observed factors that may supplement the “Yes” or “No” response. If the answer to a question is unknown because of a lack of site characterization or there is high uncertainty, it should be marked as a “Yes” to represent risk. Further investigations (e.g., data collection, testing, etc.) should be conducted to reduce uncertainty.

Choose a Table to Expand:

Table A-1: General Hydrology Checklist

This table applies to the resource types and extraction methods listed below.

|

Resource Types Brine Clay Hard rock

|

Extraction Methods Evaporative concentration Direct lithium extraction Surface strip mining Surface pit mining |

| # | Yes | No | Risk Assessment Question | |

| 1. | ¨ | ¨ | Are there perennial or intermittent springs or seeps in the hydrologic area of influence (HAI)? |

|

| Notes: | ||||

| 2. | ¨ | ¨ | Do springs or seeps in the HAI contain geothermally heated waters? | |

| Notes: | ||||

| 3. | ¨ | ¨ | Are springs or seeps in the HAI downgradient of site facilities? | |

| Notes: | ||||

| 4. | ¨ | ¨ | Are there perennial or intermittent streams, rivers, lakes, or ponds in the HAI? | |

| Notes: | ||||

| 5. | ¨ | ¨ | Are there streams, rivers, lakes, or ponds in the HAI that are downgradient of site facilities? | |

| Notes: | ||||

| 6. | ¨ | ¨ | Are there any groundwater dependent ecosystems (i.e., springs, wetlands, riparian zones) in the HAI? | |

| Notes: | ||||

| 7. | ¨ | ¨ | Does the proposed/permitted project area have a relatively large (>5,000 acres) total footprint? |

|

| Notes: | ||||

| 8. | ¨ | ¨ | Is there a high potential for erosion and sedimentation, such as excavated slopes, earthen stockpiles, or facilities constructed within the floodplain? | |

| Notes: | ||||

| 9. | ¨ | ¨ | Will groundwater pumping (e.g., during exploration and aquifer characterization activities, brine extraction, dewatering, or for freshwater operations) affect the water supply of surface-water features in the HAI? | |

| Notes: | ||||

| 10. | ¨ | ¨ | Are shallow freshwater aquifers (water table within 100 ft of land surface) present below any extraction facilities on the land surface? | |

| Notes: |

Table A-2: Lithium Brine Checklist

This table applies to the resource types and extraction methods listed below.

|

Resource Types Brine

|

Extraction Methods Evaporative concentration Direct lithium extraction |

| # | Yes | No | Risk Assessment Question | |

| 1. | ¨ | ¨ | Is groundwater/brine extracted from aquifers that are hydraulically connected to any adjacent aquifers? | |

| Notes: | ||||

| 2. | ¨ | ¨ | Will additives be used at any point during brine processing at an on-site facility (i.e., chemicals, acids, bases, etc.) |

|

| Notes: | ||||

| 3. | ¨ | ¨ | Are evaporation ponds or storage ponds used at any point during processing? | |

| Notes: | ||||

| 4. | ¨ | ¨ | Is there potential for brine extraction to lead to aquifer collapse and/or land subsidence? | |

| Notes: | ||||

| 5. | ¨ | ¨ | Are any solid wastes or by-products produced during brine processing at an on-site facility? |

|

| Notes: | ||||

| 6. | ¨ | ¨ | Are rapid infiltration basins used to return water/brine to the subsurface? | |

| Notes: | ||||

| 7. | ¨ | ¨ | Is the volume of fluid extracted from the subsurface greater than volume returned to the subsurface? | |

| Notes: |

Table A-3: Surface Mine Checklist

This table applies to the resource types and extraction methods listed below.

|

Resource Types Clay Hard rock |

Extraction Methods Surface strip mining Surface pit mining |

| # | Yes | No | Risk Assessment Question | |

| 1. | ¨ | ¨ | Will the surface mine require dewatering? | |

| Notes: | ||||

| 2. | ¨ | ¨ | Is a pit lake expected to form in the future? | |

| Notes: | ||||

| 3. | ¨ | ¨ | Will extraction include sulfide minerals, radioactive materials, or other geologic material that is a contaminant of concern? | |

| Notes: | ||||

| 4. | ¨ | ¨ | Are acidic compounds used during processing that will be contained in tailings facilities? | |

| Notes: | ||||

| 5. | ¨ | ¨ | Are tailings facilities constructed using any method other than the best available technology? Best available technology as of 2022 is dry filtered tailings with drainage (Morrill et al., 2022). | |

| Notes: | ||||

| 6. | ¨ | ¨ | Will tailings fluids discharge directly into the environment (i.e., seepage into the subsurface or leachate that drains onto the surface or into a pond)? | |

| Notes: |

Hydrologic Impacts Framework

5.1 PRE-DISTURBANCE:

5.1.1 SURFACE-WATER HYDROLOGY

What is known about surface-water conditions prior to land disturbance and extraction activities?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine, clay, hard rock |

| Extraction Methods | evaporative concentration, direct lithium extraction, surface strip mining, surface pit mining |

| Surface-water Features to Consider | seeps and springs, streams and rivers, lakes and ponds, wetlands, riparian areas |

1. Have surface-water features in the project area been adequately identified and characterized?

a. If yes, characterization and monitoring efforts should continue.

b. If no, a surface-water survey should be conducted, inventory created, and features characterized.

2. What is the location of each surface-water feature with respect to project boundary and facility activities?

a. If the surface water is within the proposed/permitted project boundary, downstream/downgradient, or upstream and hydraulically connected, there should be high consideration for potential impacts.

b. If no hydraulic connection and upstream of the project area, or at a distance/location outside of hydrologic area of influence (HAI), less consideration for potential impacts.

3. Is flow perennial, intermittent, or ephemeral and what are the sources of water?

a. If flow is perennial (continuous flow year-round) or intermittent (continuous flow during certain times of the year) with baseflow contribution from local groundwater (directly from the aquifer or from seep/spring discharge), high consideration for potential impacts.

b. If flow is ephemeral (flowing or pooling only in response to precipitation), there is lower potential for impacts. It is important to note that there is not always a clear distinction between flow classifications (i.e., perennial, intermittent, ephemeral) or the classification may change over time. For example, a drainage that has ephemeral flow during drought conditions may have intermittent flow during wet cycles.

c. If geothermally heated springs are present that support sensitive aquatic habitat, additional considerations should be made, including comprehensive hydrologic and hydrogeologic field assessments and the development of numerical models to quantify the expected hydrologic impacts.

4. Have surface-water quantity and quality baseline conditions been established (i.e., flow, stage, temperature, physical parameters, geochemistry) for average, dry, and wet conditions over multi-year, annual, and seasonal timescales?

a. If yes, monitoring should continue through all pre-extraction, extraction, and post-extraction periods.

b. If no, a monitoring program should be designed and implemented to define the natural range of variability of all hydrologic baseline parameters on all necessary timescales.

5. Do the surface-water features support groundwater dependent ecosystems (GDEs) (i.e., wetlands, riparian zones, seeps, springs)? Do any GDEs provide habitat for protected species, endemic species, etc.?

a. If yes to either of these questions, additional considerations should be made with respect to hydrologic impacts on ecosystem health. This should be considered during all monitoring and mitigation phases.

b. If no GDEs or protected species, monitor for the development of GDEs.

5.1.2 GROUNDWATER HYDROLOGY

What is known about groundwater and aquifer conditions prior to land disturbance and extraction activities?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine, clay, hard rock |

| Extraction Methods | evaporative concentration, direct lithium extraction, surface strip mining, surface pit mining |

1. Has the spatial variability of groundwater conditions (water levels, hydraulic gradients/flow paths, water quality) been adequately defined? Sources of these data may include in situ water-level measurements via observation wells, satellite data, water-sample collection, etc.

a. If yes, monitoring should continue through the life of the project.

b. If no, site and install additional groundwater observation wells for in situ measurements of water quantity and quality.

2. Has the temporal variability of groundwater conditions been established (e.g., groundwater levels, hydraulic gradients, water temperature, physical parameters, geochemistry) for average, dry, and wet conditions over annual, seasonal, and short-term timescales.

a. If yes, monitoring should continue through the life of the project.

b. If no, a monitoring program should be designed and implemented to define the natural range of variability of all hydrologic baseline parameters at all relevant timescales. Additional observation wells should be sited and installed as necessary.

3. Has a groundwater budget been prepared to account for all inflows and outflows of the aquifers of interest (i.e., freshwater, brine)?

a. If yes, does the groundwater budget consider all relevant scales (i.e., project area, HAI, basin wide). At a minimum, a groundwater budget should be prepared for the HAI with an additional buffer to account for uncertainty in HAI delineation.

b. If no, a groundwater budget should be prepared.

4. Has an aquifer characterization been performed to delineate hydrostratigraphic units, aquifer extent/boundaries, and aquifer connectivity to adjacent aquifer systems and surface waters?

a. If yes, were aquifer pumping tests conducted as part of the hydrogeologic characterization?

b. If yes, consider this information when developing the hydrogeologic conceptual model.

c. If unconfined, consider the hydraulic connection to surface waters, springs, and GDEs.

d. If confined, consider that high aquifer pressure may affect flow if drilling is conducted.

e. If no, aquifer testing should be conducted at the scale necessary to accurately characterize the aquifers over the area of interest (e.g., HAI).

5.2 LAND DISTURBANCES AND INFRASTRUCTURE:

What are the potential hydrologic effects of land disturbances and new or modified infrastructure?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine, clay, hard rock |

| Extraction Methods | evaporative concentration, direct lithium extraction, surface strip mining, surface pit mining |

| Disturbances May Be Associated with at Least the Following Facilities | roads, power lines, buildings (e.g., processing facilities, offices, etc.), wells and well pads, open-pit/strip mines, waste-rock storage, processing/evaporation ponds, rapid infiltration basins, mine tailings, surface-water diversions, canals, culverts |

1. For all facilities and land disturbances: What is the type, quantity, area (i.e., footprint), depth (if applicable), and location? To what degree will existing facilities be used?

a. If there is no existing infrastructure or facilities at the proposed extraction site, then there is a relatively high potential for hydrologic impacts.

b.If existing facilities will be used exclusively and no new facilities or modifications to existing facilities are required, there is less potential for hydrologic impacts.

2. For all facilities and land disturbances: What is the proximity of the disturbance/facility to surface water? Do they intersect surface waters? Are they located upstream of surface waters?

a. If yes to any of the above, assess possible impacts on surface water caused by erosion, sedimentation, or alterations to runoff. This may lead to the degradation or loss of the surface-water resource if facilities directly intersect it.

b. If disturbances influence surface water, alterations to runoff as well as increased erosion and sedimentation may result in degradation of local or downstream surface water.

c. If no, erosion and sedimentation may still increase depending on the scale of disturbance and the proximity to surface water.

3. For all facilities and land disturbances: Are best management practices (BMPs) in place for runoff and erosion control?

a. If yes, are they adequately designed to mitigate erosion, sediment transport, and deposition during a high-magnitude design storm, such as a 100-year flood frequency event? Were the following considered when selecting BMPs: infrastructure size, range of rainfall amounts (i.e., average, high), discharge rate and volume, type of discharge (e.g., potential for contaminated flow), and proximity to downstream surface waters? Runoff/stormwater diversions may impact inflows to downstream water resources.

b. If no, then erosion may lead to increased sedimentation in surface waters during flow events. Surface-water runoff amount and flow paths may change, impacting inflows to downgradient surface waters. Depending on the type of on-site facilities, this may also result in the release of harmful constituents into the environment.

4. Are wells to be installed for groundwater pumping and/or monitoring?

a. If yes, what drilling methods and drilling fluids will be used? What material will be used for well construction (i.e., bentonite, cement, etc.)? Is there potential for the release of harmful chemicals into the aquifer during construction? Will hydrostratigraphic units be sealed or packed to limit mixing between aquifers? Will the well head and annular space be sealed to ensure the well does not act as a conduit for surface water/contaminants to enter the subsurface? If acids are used during well rehabilitation at any point during the life of the project, additional consideration should be given to assessing impacts on water quality.

5. Will any artificial surface depressions be constructed (i.e., ponds, rapid infiltration basins [RIBs])?

a. If yes, how many process ponds and RIBs will be constructed and what are the dimensions of each? Determine the proximity of RIBs and ponds to surface water and groundwater and controls to prevent infiltration, such as liners. What is the area and volume per pond? Will artificial depressions capture precipitation during storm events or impact local runoff?

6. Will tailings or waste rock be produced during extraction activities?

a. If yes, what is the material? What is the design and dimensions of storage facilities? What is the proximity of the storage facility to surface water and groundwater? What controls are in place to prevent infiltration and contamination, such as liners. How will slopes be constructed?

5.3 EXTRACTION AND OPERATIONS:

5.3.1 LITHIUM BRINE AND FRESHWATER EXTRACTION

What are the hydrologic effects of brine and freshwater extraction and facility operation?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine, clay, hard rock |

| Extraction Methods | evaporative concentration, direct lithium extraction, surface strip mining, surface pit mining |

| Infrastructure and Processes | pumping wells for lithium-brine and freshwater, application of freshwater |

Groundwater and surface-water responses to groundwater extraction (evaluate for short and long-term cumulative impacts):

1. What are the expected hydrologic impacts on water quality and quantity associated with groundwater extraction, including brines and freshwater?

a. If expected hydrologic impacts are established with high confidence, take the necessary precautions based on these expectations (i.e., mitigation plan if impacts are expected).

b. If potential hydrologic impacts associated with extraction have not been assessed, see remaining questions in this section.

2. Has a hydrogeologic conceptual model (HCM) been developed?

a. If yes, use the HCM to make inferences about potential hydrologic impacts by considering the remaining questions in this section.

b. If no, develop an HCM and then consider the remaining questions in this section.

3. Has the hydrologic area of influence (HAI) associated with brine and groundwater extraction been established?

a. If yes, apply it when answering the following questions.

b. If no, establish the HAI considering the number, location, area, design, and pumping schedule of all pumping wells, each well’s depth and screened interval, aquifer(s) targeted, and groundwater conditions.

4. Is the brine/freshwater pumping schedule known (i.e., the volume extracted over time)?

a. If yes, does pumping occur year-round, seasonally, etc., and how might this affect water resources at these timescales?

b. If yes, what volume of brine and freshwater is extracted per year and how does this impact the annual groundwater budget, perennial yield, etc.?

c. If yes, what are the cumulative impacts of all pumping wells for the project plus other pumping wells in the basin to water resources, aquatic ecosystems, other water users/water rights? Consider potential water-quality and -quantity impacts for surface waters and groundwaters over short- and long-term scales.

d. If no, consider conservative pumping assumptions (quantities and time scales on the high end) until data are available.

5. Will groundwater and brine extraction alter the natural hydraulic gradients and groundwater flow directions? Note: If pumps are used, hydraulic gradients are always impacted because of induced hydraulic head changes in the aquifer.

a. If yes, to what extent will the gradients and flow direction be altered? How will water quality change in response to altered sediment-fluid interactions? How long until brine/water levels and quality recover in the pumped aquifer(s)?

6. Is the target aquifer hydraulically connected to adjacent aquifers?

a. If yes, how will it impact the water quality and quantity of the adjacent aquifer? How much mixing is anticipated? Is a mitigation plan in place?

b. If no, will the aquifer be fully replenished and over what time frame? What is the expected annual recharge/inflow rate to the aquifer?

7. Are any impacted aquifers hydraulically connected to surface waters?

a. If yes, are there any groundwater dependent ecosystems or special-status species? Is a mitigation plan in place?

b. If yes, what are potential water-quality and -quantity impacts? Is a mitigation plan in place?

c. If no, continue monitoring surface waters to validate the conceptual model and confirm no impacts on surface waters.

8. Is there potential for land subsidence to occur as a result of pumping? Pumping rates should be considered, as well as lithology of the pumped aquifer(s).

a. After or during pumping, if the strength of the aquifer material is less than the pressure of the overburden, there may be potential for the aquifer compaction.

9. Is freshwater being used for operations (e.g., dust or fire suppression, soil desalination, mixing with brines)?

a. If yes, how might freshwater applications impact surface-water and groundwater quality/quantity? Are best management practices in place to prevent discharged water from pooling or flowing on the land surface?

5.3.2 SURFACE MINE RESOURCE EXTRACTION

What are the hydrologic effects of lithium-clay and hard-rock extraction and facility operation?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | clay, hard rock |

| Extraction Methods | surface strip mining, surface pit mining |

| Operation Processes to Consider Including |

dewatering, excavation; storage of overburden, waste rock, and gangue; use of ponds or impoundments |

Considerations for strip mine or open-pit mine:

1. Have all materials that will be extracted and deposited been representatively sampled for geochemical analysis?

a. If yes, see remaining questions in this section.

b. If no, perform a geochemical characterization of the geologic material.

2. How will different types of material be removed/excavated? What volume of each? Where will materials be stored?

3. Will mining occur at, below, or near the water table?

a. If yes, assess groundwater impacts and evaluate dewatering techniques. What is the water quality of pumped groundwater? Will it be treated, stored, used in operations, or discharged away from the facility? Are there naturally occurring contaminants of concerns dissolved in the groundwater? What controls and mitigation are designed to prevent contaminants associated with mining operations from releasing into the excavated area?

b. If no, impacts from dewatering are less likely.

4. Will mine slopes be formed that are cut slopes or fill slopes?

a. If yes, what controls are in place to prevent slope failure? How about controls for increased erosion and rapid runoff? Will slope stability monitoring be conducted?

5. Is a pit lake expected at any point during the life of the project or post-closure?

a. If yes, is it a terminal sink or will water pass-through? Have the following been conducted for a pit lake: water balance, conceptual model, numerical model of predicted contaminant fate and transport? Will the pit lake be treated to background surface-water quality standards?

b. If yes, and mining is active, will inflows be removed from the pit to prevent ponding? How will water be removed (e.g., pumped and conveyed)?

6. Will sulfide minerals be extracted?

a. If yes, conduct an acid mine drainage (AMD) assessment and attempt to isolate wastes that may generate acid. What controls, neutralization, and treatment are in place to prevent AMD?

b. If no, AMD is unexpected as part of resource extraction, but may occur if acid is used in mineral processing (see Section 5.4.3).

7. Will naturally occurring radioactive or other contaminants of concern be extracted?

a. If yes, what is the background radioactivity or toxicity from these

sources? How will waste be handled to prevent contamination of surface

or groundwater?

Considerations for overburden and waste-rock storage:

8. How will overburden and waste rock be stored? For how long?

9. Will fluid that infiltrates through the stockpile be contained with a liner and drainage system?

a. If yes, the stockpile should be designed to drain at discharge points. If it is released into the environment, what are the water-quality concerns, mitigation solutions, and monitoring procedures at discharge points?

b. If no, but the underlying ground surface has low conductivity, infiltrated water may saturate the lower portion of the stockpile then move laterally to toe seeps. Evaluate water-quality concerns at toe seeps.

c. If no and the underlying ground surface has mid- to high-conductivity, uncontrolled seepage into soil and groundwater is expected. Evaluate the water-quality risks, mitigation, and monitoring for groundwater.

Considerations for ponds:

10. What is the type of pond (i.e., tailings, processing)? How will fluid and sediment be contained?

a. If it is a tailings pond, see Sections 5.4.3 #10 and #11.

11. Will there be potential for contaminants at high concentrations in ponds?

a. If yes, what treatment, mitigation, and monitoring are in place? Have alternatives been considered?

12. Will water be reused for facility operations?

a. If yes, consider the pollution potential at its end use and evaluate if treatment is necessary.

b. If no, treated discharge should be of similar quality to background surface water and compliant with regulatory guidance.

13. What measures are in place to reduce leakage from the pond into the subsurface? See Section 5.4.1 #3 for pond leakage and design considerations.

Considerations for transportation of excavated materials:

14. Are aboveground or underground storage tanks used for fuel storage? Will pipelines be used for ore slurry or fuel?

a. If yes to either question, characterize the material stored, the tank/pipe construction, leak-detection system, and proximity to active faults, surface water, and groundwater.

b. If no, evaluate any other engineered systems for chemicals used during transportation of excavated materials.

5.4 RESOURCE PROCESSING:

5.4.1 LITHIUM BRINE: EVAPORATIVE CONCENTRATION

What are the hydrologic impacts of lithium-brine processing using evaporative concentration techniques?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine |

| Extraction Methods | evaporative concentration |

Water-quality considerations:

1. Once the brine has been extracted from the subsurface, will additives be used during the evaporative concentration process to precipitate unwanted ions/salts and create a concentrated lithium brine?

a. If yes, what are the specific additives used and quantities applied, and at which stage/pond? Will acids and bases be used to control pH at various stages? What are the on-site facilities and best management practices (BMPs) for additive storage?

2. Will any solid waste or by-products be produced during the evaporative concentration process?

a. If yes, will mineral compounds be precipitated from the brine (e.g., halite, sylvite, calcite, gypsum)? If so, in what sequence (at which stage/pond) and at what rate? How are solid waste and by-products stored, treated, and transported? For example, will precipitated material be dredged from the pond and transported to stockpiles or a sludge-containment reservoir?

3. Are there measures in place to reduce leakage and detect leakage from the evaporation pond into the subsurface?

a. If leakage reduction relies on low-permeability soils beneath and surrounding the pond, has a soil survey been conducted? Is a continuous low-permeability layer present beneath the pond and if so, what is the depth to the top of the layer and its thickness? How are any permeable soil zones managed (e.g., replaced with low permeability clays)?

b. If pond liners are used, what kind of material is used (Hypalon, polyvinyl chloride, polypropylene)? How are strips combined/sealed (e.g., adhesive, welding)? Are all liners leak-checked prior to use? Is a leak detection system co-installed with the liner?

c. Are precipitated salts used to reinforce the pond floor/walls?

d. What measures are taken to monitor for leaks in the subsurface (i.e., conductivity, temperature, and/or moisture sensors; piezometers)? If a leak is detected, is an action plan in place to find and repair the leak?

4. Are any additional processes used to augment the evaporative concentration process that could impact water quality directly or indirectly?

a. If yes, what are the techniques, what materials/additives are needed? For example, the use of alumina columns for selective adsorption or co-precipitation of lithium.

5. Is the transfer of brines between ponds driven by pumps?

a. If yes, how are pumps powered (e.g., diesel generators)? What BMPs are in place for all fuel storage, conveyance, etc.?

b. If no, does the method of transfer (e.g., gravity or another technique) pose risk for surface or groundwater contamination?

6. Will lithium-depleted brine be returned to the subsurface via reinjection wells or rapid infiltration basins (RIBs)?

a. If yes, how will the lithium-depleted brine be conveyed to the RIBs/injection wells (e.g., gravity fed or pumped through pipeline)?

b. If yes, will the proposed technique return the lithium-depleted brine to the source aquifer or a different aquifer? A great potential hazard is posed if fluid originally from a brine aquifer is infiltrated or injected into a freshwater aquifer.

c. If yes, how does the water quality of the return brine compare to the quality of the aquifer fluid? If RIBs are used, has an assessment of shallow water quality been conducted? Has geochemical characterization of the sediment in the unsaturated and saturated zones been performed?

7. Upon completion of the evaporative concentration process, is the lithium-concentrated brine refined on-site?

a. If yes, what additives, acids, etc., and procedures are used to produce the final lithium product? What are the BMPs in place for storing, transporting, and using these materials to prevent spills, contamination, etc.? Additives may include chemicals, acids, and bases that could degrade water quality if there is an environmental release.

b. If no, the lithium-concentrated brine is transferred for off-site processing. What BMPs are in place for transporting the brine? Is the brine transferred via a pipeline using pumps, trucked, shipped by railroad? What is used to power any pumps (e.g., diesel generators)?

8. Post-refinement, is any slurry or filtrate returned to the solar pond for further processing for lithium (or other materials of interest)?

a. If yes, what methods will be used to convey/transport these materials and what are potential threats to water quality?

b. If yes, the evaluation process should recommence at Section 5.4.1 #1.Water-quantity considerations:

9. Will water from the brine be removed through evaporation?

a. If yes, what volumes of brine and freshwater are consumed through evaporation and for extraction operations over varying time frames (seasonal, annual, life of the project). What percent of the total volume extracted is lost to evaporation? How many ponds are used, what are the pond dimensions, how much brine per pond, and what are the evaporation rates per pond? How do seasonal differences between evaporation and precipitation rates impact processing timing, duration, and total water loss? Are any steps taken to reduce evaporation or recapture evaporated water? What is the initial lithium concentration of the extracted brine and how is this concentration expected to change over time? How do lithium concentrations relate to the extracted brine volume (and volume evaporated)?

10. Will lithium-depleted brine be returned to the subsurface via reinjection wells or RIBs?

a. If yes, what is the anticipated volume of brine, treated water, etc., infiltrated (through RIBs) or reinjected (through wells) into the subsurface? What percentage of the volume pumped from the brine aquifer is returned to the aquifer? Reinjecting or infiltrating brines/waters result in a temporary and localized increase in water pressure, or groundwater “mounding,” that will alter natural groundwater flow paths. If brine is returned to a shallow aquifer that is connected to surface water, will surface-water flow/stage be impacted? Could this have an impact on groundwater dependent ecosystem, special-status species, or other water users/water rights holders?

11. Is freshwater needed during processing?

a. If yes, how much freshwater is needed during processing and what is the source of the freshwater? For example, freshwater may be used during refinement to prevent salts from crystallizing. If water is sourced from local freshwater aquifers, what are the hydrologic impacts (see Sections 5.3.1 #4 and #5).

5.4.2 LITHIUM BRINE: DIRECT LITHIUM EXTRACTION

What are the hydrologic impacts of lithium brine-processing using direct lithium extraction?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine |

| Extraction Methods | direct lithium extraction |

Water-quality considerations:

1. Once the brine has been extracted from the subsurface, will direct lithium extraction (DLE) be performed at on-site facilities?

a. If yes, see questions below.

b. If no and transferred to an off-site processing facility, what are the transportation logistics and BMPs in place to prevent environmental releases during transfer?

2. Is the DLE technique known? Many DLE techniques are proprietary and limited information may be available.

a. If yes, what is the DLE technique?

b. If yes, will additives be used to convert the original lithium compound to the final lithium product? What are the additives, what volumes will be added, and at which stage of the extraction process? For example, sodium carbonate may be added to convert lithium chloride to lithium carbonate. What is the pH of the incoming brine, and will acids/bases be used to control pH? Will brine polishing take place to remove unwanted ions (e.g., pass brine through ion-exchange system to replace magnesium and calcium with sodium)?

c. If no, there may be relatively greater risk for hydrologic impacts. Assume greater risk until the processing technique is known and associated hydrologic risks identified.

3. Will lithium-depleted brine be returned to the subsurface via reinjection wells or RIBs?

a. If yes, see Section 5.4.1 #6.Water-quantity considerations:

4. Will lithium-depleted brine be returned to the subsurface via reinjection wells or RIBs?

a. If yes, see Section 5.4.1 #10.

5.4.3 SURFACE MINE RESOURCE PROCESSING

What are the hydrologic impacts of lithium-clay and hard-rock processing?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | clay, hard rock |

| Extraction Methods | surface strip mining, surface pit mining |

1. What chemicals are present on-site for the separation, roasting, acid leaching, precipitation/purification, conversion processes for the refinement of the final lithium product?

2. Are the chemicals potentially hazardous if released into the environment?

a. If yes, evaluate their potential for surface-water and groundwater contamination. How easily can it mobilize into the environment? Is the substance water soluble? Evaluate each substance’s polarity, specific gravity, and potential for conversion or biological transformation.

3. Will hazardous chemicals be stored in aboveground or underground storage tanks? Are pipelines also used?

a. If yes to any, characterize the material stored, the tank/pipe construction, leak detection system, and proximity to faults, surface water, and groundwater.

b. If no, evaluate any other engineered systems for transportation and storage of hazardous chemicals used in processing.

4. Will acidic compounds be used in processing?

a. If yes, conduct an acid mine drainage (AMD) assessment. Isolate wastes that may generate acid and neutralize this waste. What controls and treatments are in place to prevent AMD?

b. If no, AMD is unexpected as part of processing but may occur if sulfide minerals are extracted (see Section 5.3.2 #6).

5. Is waste from processing mixed with waste from extraction?

a. If yes, evaluate waste management procedures to address water-quality concerns for all combined material.Considerations for solid waste from processing:

6. Determine the type of material and storage method. Is the best available technology employed?

7. Will solid waste be treated prior to storage/disposal?

a. If yes, determine the method and efficiency of treatment.

b. If no, analyze water-quality risks associated with untreated waste. What is the potential for contamination of surface-water runoff or groundwater seepage? Will there be water-quality monitoring?

8. Will fluid that infiltrates through the tailings facility be contained with a liner and drainage system? Will the facility be zero discharge?

a. If yes, but not zero discharge, drained water will be concentrated at discharge points and released into the environment. What are the water-quality concerns, mitigation solutions, and monitoring procedures at discharge points?

b. If no, are there other engineered controls to prevent infiltration and seepage? What are the water-quality concerns, mitigation solutions, and monitoring procedures for surface water and groundwater?

9. Will tailings be deposited into an excavated area?

a. If yes, analyze BMPs to mitigate seepage of leachate into soil and groundwater. If seepage is possible, what compounds could be mobilized? Will there be water-quality monitoring? What is the predicted fate and transport of leached constituents?Considerations for tailings pond or liquid waste from processing:

10. Determine the type of material and storage method. Will a tailings pond or subaqueous tailings be used?

a. If yes, these methods should be reconsidered because they are potentially hazardous to environmental safety, especially if an upstream dam is used. What are the treatment, stability monitoring and water-quality monitoring, mitigation, and containment procedures?

b. If no, is liquid waste from waste rock, dry-stack tailings or seepage collected? Analyze water-quality risks associated with waste. What is the potential for contamination in surface-water runoff or groundwater seepage?

11. Are ponds designed to be impermeable with zero discharge?

a. If yes, the pond will retain water, which may reduce dam stability and increase the risk of overtopping or failure. See Section 5.4.1 #3 for pond leakage concerns. How will overtopping be prevented during normal operations? During flooding events? What is the slope-stability monitoring plan?

b. If discharge is expected, assess flow paths, and water quality at the discharge point. Are BMPs designed for contamination prevention and mitigation?

c. If the pond is not impermeable but no discharge is expected, seepage will occur into groundwater and through the embankment face. What compounds could be mobilized? What is the predicted fate and transport of leached constituents?Considerations for both solid and liquid waste:

12. Will surface-water resources and associated ecosystems be severely impacted if tailings fail to contain contaminants?

a. If yes, tailings failure is accompanied by high consequences and the tailings disposal method and location should be critically analyzed or reconsidered.

13. Does the surface-water and groundwater management plan address the potential water-quality impacts associated with tailings?

a. If yes, are impacts on short-term and long-term water quality sufficiently mitigated with a high degree of certainty, especially where contaminants could reasonably affect surface-water habitat or groundwater dependent ecosystems?

b. If no, identify and resolve overlooked or uncertain systems. Tailings are a major pollutant source.

5.5 CLOSURE OF A LITHIUM EXTRACTION FACILITY:

What are the hydrologic impacts related to facility closure activities?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine, clay, hard rock |

| Extraction Methods | evaporative concentration, direct lithium extraction, surface strip mining, surface pit mining |

| Areas/processes to consider include | regrading and revegetation, facilities (e.g., processing, fueling, etc.), open-pit or strip mine, waste-rock storage, ponds, rapid infiltration basins, tailings |

1. Will surface conditions (e.g., topography, grade, soil, vegetation) be restored to pre-extraction conditions?

a. If yes, over what time frame?

b. If yes, what are the best management practices to reduce impacts on erosion, stormwater, and sedimentation as facilities are deconstructed and removed and the land is regraded?

c. If yes, when will revegetation to pre-extraction levels be achieved? Prior to vegetation regrowth and root development, soil stability may be compromised. Erosion from wind and water, as well as slope failure can result in sedimentation of surface waters. Pre-extraction evapotranspiration rates may not be achieved until vegetation is fully grown. How will this impact the local and regional water balance, surface-water flow, etc.?

d. If no, where will land-surface conditions not be restored? What are the short- and long-term hydrologic effects of not returning these areas to pre-extraction conditions (i.e., runoff, erosion, and sedimentation)? What about impacts on excavated areas, such as groundwater/surface water interaction at a pit lake?

2. Will subsurface conditions (e.g., groundwater levels and flow paths, water chemistry, soils) be restored to pre-extraction conditions

a. If yes, how will this be achieved? Will pumping wells be plugged and abandoned to prevent surface contaminants from migrating downward through the well/borehole? If a surface mine required dewatering, will water levels completely recover? How long after pumping stops will water levels rebound?

b. If no, what will be the long-term consequences for water resources?

3. Will excavated areas be backfilled?

a. If yes, what are the methods to backfill surface depressions? Will the original rock/soil/sediment be used for backfilling? If the original stratigraphy is altered, how will the presence of homogenized/disturbed rock and soil impact soil physics, water infiltration, groundwater levels, and surface-water discharge?

b. If yes, has the original geologic material been exposed to the atmosphere? The material may be oxidized, which can change geochemical conditions. How might this impact water quality as water percolates through the disturbed rock or soil? Focus should be put on increased potential for leaching metals, acid mine drainage, and impacts on hydraulically connected surface-water bodies. Geochemical models can be developed to predict long-term effects to water quality associated with water-rock interaction.

c. If no, what are the geochemical implications to surface water and groundwater of not restoring these areas and leaving them exposed to the atmosphere, precipitation, etc.?

d. Are surface water and groundwater being monitored for water-quality and quantity impacts during closure? What is the hydraulic connectivity between areas used for ponds, rapid infiltration basins, tailings, excavation/backfill and surface-water and groundwater systems? Impacts on groundwater and surface water may be the result of delayed impacts of extraction activities or directly related to closure activities (e.g., regrading). Aquifer hydraulic properties may cause delayed groundwater and surface-water impacts, such as aquifers with low hydraulic conductivity that promote long residence times.

5.6 POST-CLOSURE OF A LITHIUM EXTRACTION FACILITY:

What are the hydrologic impacts post-closure of a lithium extraction facility?

This subsection applies to the following resource types, extraction methods, and surface-water features.

| Resource Types | brine, clay, hard rock |

| Extraction Methods | evaporative concentration, direct lithium extraction, surface strip mining, surface pit mining |

1. Once the lithium extraction site has been reclaimed, will surface-water and groundwater monitoring continue to identify any long-term impacts?

a. If yes, will data collection be adequate to identify any long-term or delayed effects to surface water and groundwater from extraction activities (e.g., resource extraction, processing) and closure activities (e.g., restoration, reclamation)? What type of monitoring will be performed (i.e., groundwater/surface water quantity/quality)? What is the duration and frequency of data collection? Is monitoring adequate to identify any unexpected chemical releases into the environment (e.g., leakage through lined facilities)?

b. If yes and there was an open-pit mine, will a pit lake remain on-site? If yes, see pit-lake guidance in Section 5.3.2 #5.

c. If no, a surface-water and groundwater monitoring plan should be developed that addresses potential impacts on long-term surface-water and groundwater quantity and quality.

2. Will the physical stability of tailings and mine slopes be monitored? Will this be coupled with groundwater seepage monitoring

a. Assess stability by evaluating the slope angle and the internal mass strength. What is the factor of safety to prevent failure?

b. If surface mining, are caps and covers (such as on tailings) adequately designed for the current climate and for climate change scenarios with increased extreme weather intensity and frequency?

c. If no, a monitoring plan should be developed. Slope failure will have significant consequences for erosion and sedimentation, as well as containment of pollutants.

3. Will the long-term environmental geochemistry be evaluated and managed?

a. If yes, what is the potential for negative changes in geochemistry over time, such as the development of an oxidizing environment, materials that exceed their acid-buffering capacity, or hydrothermal alterations?

b. If yes, will numerical models predict contaminant fate and transport for a range of conditions that address uncertainties? Does it have a sufficiently long period of prediction?

c. If yes, will monitoring be conducted at observation points (surface water or wells) to verify or inform predicted concentrations, timing, and extent, which can be used to calibrate and update performance predictions?

d. If yes, will remediation occur if concentrations exceed predetermined thresholds? What will remediation entail?

e. If no, considering developing a geochemical modeling and monitoring plan. A numerical model can be developed to predict contaminant transport and fate. Monitoring plans are useful to verify or update the geochemical model.